Introduction: As cities strive toward net-zero targets, air source heat pumps (ASHP) have become a cornerstone of commercial decarbonisation strategies. Yet, when installed in densely populated areas, these otherwise efficient systems can present a critical design challenge: noise.

For M&E contractors, specifiers, and consultants working on heat pump projects in urban environments, acoustic performance is no longer a secondary concern—it’s central to compliance, planning approval, and occupant satisfaction. This guide outlines the risks, regulatory context, and best practices for ASHP noise mitigation.

Why Noise Control is Essential in Urban Projects

- Regulatory Compliance: British Standard BS 4142:2014+A1:2019 sets out how to assess sound from external equipment against the existing background noise level.

- Planning Requirements: Many local authorities require pre-installation acoustic reports and enforce strict noise limits, especially at night.

- Neighbour Relations & Client Risk: Noise complaints can delay handovers, tarnish reputations, and lead to costly mitigation retrofits.

Understanding ASHP Noise Sources

- Compressor Noise: Can emit significant tonal or cyclic sound, especially during start-up.

- Fan Noise: The primary airborne sound source; varies with size and speed.

- Defrost Cycles: Often louder in cold conditions, with noticeable shifts in operating tone.

- Vibration Transmission: Poor isolation can transmit structure-borne noise through brackets, pipework, or floors.

- Number of ASHP’s – dB levels will increase incrementally with each additional ASHP added to your design.

Key Mitigation Strategies for M&E Contractors

- Select Low-Noise ASHP Units:

- Choose units with sound power levels under 65 dB(A) where possible.

- Inverter-driven compressors and EC fans produce less tonal noise and enable quieter night modes.

- Strategic Unit Placement:

- Avoid corners and reflective surfaces that amplify noise.

- Roof installations can reduce sound propagation to neighbor’s but require vibration isolation.

- Maintain distance from windows and residential facades—doubling distance can reduce perceived sound by 6 dB.

- Vibration Isolation:

- Use anti-vibration mounts and flexible pipe connectors.

- Mount equipment on mass-loaded bases where feasible.

- Install Acoustic Barriers or Enclosures:

- Include open-top acoustic screens or louvres.

- Ensure airflow is not restricted—blocked airflow leads to inefficiency and increased noise.

- Acoustic Pre-Checks & Simulations:

- Use ISO 9613-2 or EN 12354 sound propagation models during design phase.

- Commission a qualified acoustic consultant to assess site conditions.

Specification Considerations for Consultants & Designers

- Clarify Manufacturer Data:

- Distinguish between sound power and sound pressure levels.

- Request data at multiple distances and angles, especially if multiple units are involved.

- Design to Night-Time Limits:

- Typical night-time target: max 35 dB(A) at nearest noise-sensitive receptor.

- Specify ASHPs with programmable night modes.

- Incorporate Acoustic Products Early:

- Consider proprietary enclosures, barriers, and attenuators in spatial planning.

- Ensure specified solutions are compliant with EN 12102-1 and maintain service access.

- Collaborate Across Disciplines:

- Acoustic specialists should feed into RIBA Stages 2–4.

- Include acoustics as a key part of post-occupancy evaluation (POE).

Example Specification Clause: “ASHP systems shall not exceed 5 dB(A) above background noise level at the nearest sensitive receptor, measured in accordance with BS 4142. Noise control strategies shall include anti-vibration mounts, acoustic screening, and programmable low-noise night operation as required.”

Quick Reference Checklist:

- Sound power <65 dB(A)

- Site-specific acoustic model pre-installation

- Vibration isolation for base and pipework

- Acoustic louvres or enclosures where space permits

- Manufacturer data sheets compliant with EN 12102

- Noise risk review in planning submission

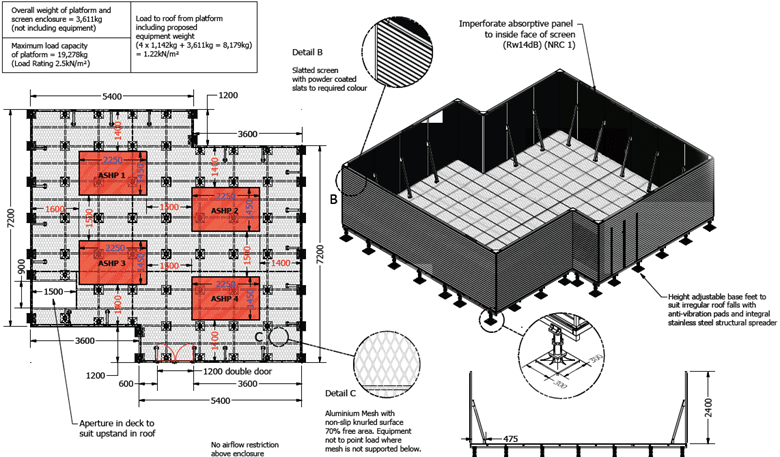

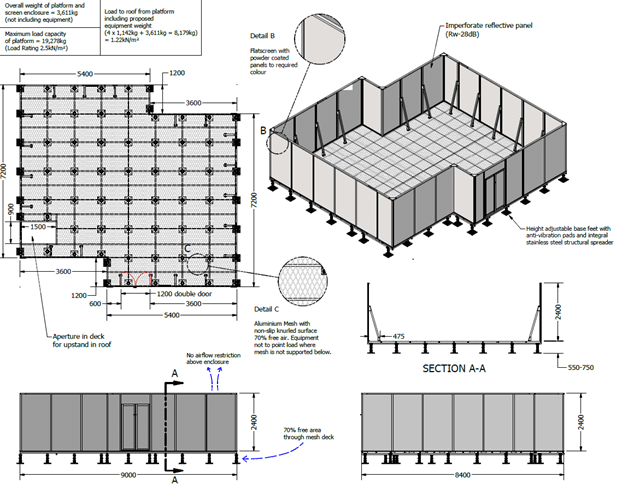

Examples of effective attenuation

Fig 1 – Raised platform and attenuated plant space offering 14dba reduction.

Fig 2 – Raised platform and attenuated plant space offering 28dba reduction.

Conclusion

For urban decarbonisation projects using ASHPs, noise mitigation is not a ‘nice to have’—it’s essential. By engaging acoustic principles from the earliest design stages and specifying performance-led solutions, M&E contractors and consultants can ensure compliance, minimise risk, and deliver high-performance heating systems that work for everyone—residents, planners, and building owners alike.

Sound planning leads to sound outcomes. Prioritise acoustics to future-proof your heat pump project.