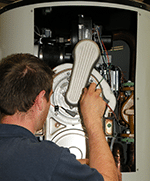

Being a service technician for a heating manufacturer might not sound glamorous, but it has taken Lochinvar’s Louis Stratford to Ghana and Mauritius as well as all parts of the UK and Ireland. And you can keep your desk jobs as far as he is concerned.

Louis Stratford grew up wanting to be a fireman, but instead has been a service technician for heating equipment manufacturer Lochinvar for ten years. Any regrets?

‘No. It’s true that it was always going to be the fire brigade for me, but when I left Banbury College at 17 there were no vacancies – so I started looking for Plan B.’

He knew he wanted to work with his hands and with a father in construction and cousin in plumbing; he turned his attention to the building services sector. Locally-based manufacturer Lochinvar was recruiting apprentices and Louis hasn’t looked back.

Since then he has had a practical and academic education paid for by his employer. This involved travelling to Southampton on block release four days a month for three years to gain his City & Guilds gas qualification. The rest of the time he was learning on the tools shadowing the experienced technicians carrying out commissioning, servicing and warranty work as well as some plumbing, pipework installations. He also gained his NVQ level 3 in installation and commissioning during that period and continues to update his qualifications.

Stuck

‘I didn’t know anything back then, but I enjoyed it from the start,’ says Louis. ‘I loved working in a different place every day and not being stuck in an office.’

Today Louis is a fully fledged service technician with an apprentice of his own shadowing his every move. ‘I try to remember what was like for me when I started and that helps me to be patient and encouraging,’ he says.

Lochinvar’s team of directly employed service technicians is supplemented by strategically located and fully trained service partners, which allows the company to cover the whole country.

‘It is a tight knit team, but we are always adding to our skills and expanding our reach,’ says service manager Paul Mitchell. ‘We plan to add another apprentice to our team in the near future and see nurturing home grown talent as essential to the company’s development.’

The trips to Ghana and Mauritius are not typical examples of a day in the life of a service technician, but they do show the possibilities and variety of work offered by the industry.

‘We supplied 70 water heaters to a project in Mauritius and, although we were able to test them here, they use different gas [propane butane mix] so we had to customise them and commission them on site. That meant a 10-day trip over there, which can’t be bad,’ recalls Louis.

He also worked on two water heaters in a temple in Ghana. ‘It was a beautiful place with marble everywhere, although it was right next to the shanty towns – a place of real contrast and a fascinating experience for me,’ he remembers.

But what about a more typical day in the life of a manufacturer’s service technician? It actually starts the day before, around 3pm, when Louis receives his work schedule for the following day via email to his laptop. This allows him to check whether he needs to call into the Lochinvar headquarters to pick up replacement parts.

Louis lives just outside Banbury in a village called Hook Norton. Most of his service work is in the South of England or the Midlands, but occasionally he may be needed to go further afield.

‘I try to get to my first job by 9am – and it really could be anywhere so satnav is pretty important. If it is a commissioning job, we need to be there for the site contractor’s induction meeting where they cover safety issues; check our CSCS cards and so on.’

So, depending on where he is going, Louis might have an early start. There is also a good chance he will go past a 5pm finish and sometimes an overnight stay in a local B&B is need if he is too far from home.

‘Our work varies between fault finding and commissioning new equipment as well as some occasional servicing,’ says Louis, who is currently particularly busy in hotels, schools and healthcare premises.

Technology

‘What we do hasn’t changed a lot in my ten years, but the technology has moved on. It used to be primarily atmospheric water heaters and boilers, but now due to energy efficiency regulations there is a lot more condensing around and they are much easier to service. With the old systems you had to strip the units right down and deal with multiple burners, but now there are fewer elements and all the electronics are on one PCB.’

‘What we do hasn’t changed a lot in my ten years, but the technology has moved on. It used to be primarily atmospheric water heaters and boilers, but now due to energy efficiency regulations there is a lot more condensing around and they are much easier to service. With the old systems you had to strip the units right down and deal with multiple burners, but now there are fewer elements and all the electronics are on one PCB.’

The increased amount of electronics is good news as far as he is concerned. ‘I am very comfortable with it. We just plug in and the appliance tells us what is wrong – that saves a lot of time.’ In fact, he believes what was formerly the m&e industry is now much more ‘e’ than ‘m’.

‘It’s always great to be able to add new skills and we are doing the 17th edition [wiring regulations] training now because the electrics are now the key thing.’

However, traditional skills still come in very handy. ‘If you find that a fuse has blown, it is important to try and find out why it blew – not just replace it – otherwise you will be back there the next day because it could easily blow again,’ he says. ‘Fault finding gives me most satisfaction. It is a great feeling to be able to find out what the problem was and put it right.’

Another common fault is fire alarm tests tripping out the main gas supply. ‘We also encounter many installations with insufficient gas pressure causing the boiler or water heater to lock out. The occupants will usually blame the boiler, but it is much more likely to be an external issue,’ says Louis.

Another common fault is fire alarm tests tripping out the main gas supply. ‘We also encounter many installations with insufficient gas pressure causing the boiler or water heater to lock out. The occupants will usually blame the boiler, but it is much more likely to be an external issue,’ says Louis.

The job does have its share of frustrations: ‘We send a pre-commissioning check list to make sure the equipment is installed and ready for commissioning, but you’d be amazed how many times we have turned up and something hasn’t been done so we can’t commission.

‘Commissioning can be a problem when too much equipment has been crammed into the plant room and this also creates ongoing access problems for servicing.’

However, Louis says the Lochinvar team always try to be helpful. ‘The customer needs the installation signing off so we will stay and help them out if possible and practical.’

With a cascade boiler installation, the engineers will make sure all the boilers, other than the one they are working on, keep running. ‘You can’t just shut the whole system down,’ he says. ‘You will soon get some pretty strong complaints if you do that kind of thing. You have to think about the customer and what they need.’

Once the work is done, Louis has to fill out a commissioning sheet and then write a report using a standard template, which gets emailed back to the office in Banbury. Then it is time to pick up the schedule for the next day before heading for home.

‘The driving can occasionally get a bit tedious, but it’s not every day and anyway it’s part of the job and I’m used to it. I’m just not suited to sitting in an office. I would only do that if I couldn’t physically do the onsite work anymore.’

He hopes to expand his skills even further by working on the company’s renewables equipment in the future. Lochinvar are very active in that market and customers are asking lots of questions about the Renewable Heat Incentive, says Louis.

So would he advise other young people to follow in his footsteps?

‘Yes, definitely. It is really challenging and if you like technology there’s lot to have a fiddle with,’ he says. It is particularly suited to people who enjoy working with electronics. We work on integrated controls with the BMS contractor to set up the fault alarm signals etc. There is a lot of technology involved in making the systems more user friendly because, at the end of the day, people expect to be able to press a button and get their heating or hot water.

‘It is our job to make that happen and it is very satisfying when we make something that technical seem so easy.’