Heat pumps are divided into 2-pipe and 4-pipe systems. We will explain the difference between the two.

2-Pipe System Heat Pump

One circuit, two functions: Heating or cooling

With a 2-pipe system, a heat pump can heat and cool, but not simultaneously. The delivery circuit with water as medium is either supplied with heated water for space heating or Domestic Hot Water DHW or the delivery system is supplied with cooled water for space cooling. 2 Pipe ASHPs are optimised and designed for the delivery of DHW and LTHW

4-Pipe System Heat Pump

Independent circuits: Heating and cooling at the same time

With a 4-pipe system, it is possible to heat or cool separately or to cool and heat simultaneously. 4 Pipe ASHPs are typically optimised for LTHW and Heat recovery from any cooling process.

In the 4-pipe system two (sub)systems can be distinguished:

System 1: P4U – Heating and Cooling

The heat pump is equipped with a cold CHW side and a warm LTHW side that can be controlled independently of each other. The device has four connections for this, two for hot water and two for cold water. Instead of one plate exchanger, there are two plate exchangers; one for hot and one for cold water. This means that the devices can heat or cool, or heat and cool simultaneously. The latter option provides the best efficiency of the heat pump because there is recovery when heating and cooling simultaneously.

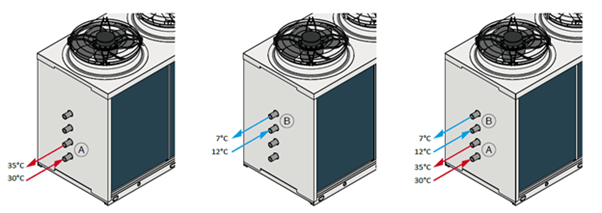

So there are 3 operating states:

- Heating: The appliance functions as a normal air/water heat pump and uses the finned heat exchanger on the source side and the plate exchanger of circuit A on the output side.

- Cooling: The unit functions as a normal air/water chiller and uses the fin heat exchanger on the source side and the plate exchanger of circuit B on the discharge side.

- Simultaneous Cooling and Heating: The appliance behaves as a water/water heat pump and uses the plate exchanger for heating circuit A and the plate exchanger for cooling circuit B.

System 2: P4S – Heating, Cooling & DHW

System 1 is not suitable for DHW. System 2 is and works as follows:

The heat pump is equipped with one side for heating or cooling and one for DHW. This device also has four connections, but now two for space heating or cooling and two for Domestic Hot Water.

Either a hot side and a cold side that can be controlled independently of each other.

This system also has two heat exchangers. One for DHW and one for Chilled Water CHW. This means that the appliances can either heat or cool, or, for the best possible efficiency, simultaneously heat and cool tap water DHW. The best possible efficiency is achieved because there is recovery when simultaneously operating tap water and cooling.

The plate exchanger for domestic hot water is optimized for the higher set value in domestic hot water operation.

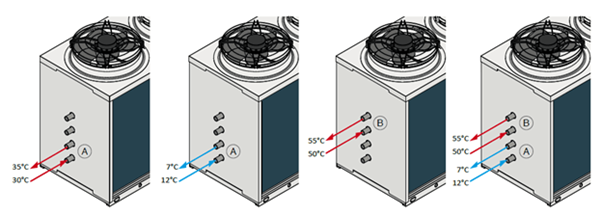

P4S ASHP’s have 4 operating states:

- Space Heating: The unit functions as a normal air/water heat pump and uses the finned heat exchanger on the source side and the plate exchanger of circuit A on the output side.

- Space Cooling: The unit functions as a normal air/water chiller and uses the fin heat exchanger on the source side and the plate exchanger of circuit A on the discharge side.

- Domestic Hot Water Operation: The appliance functions as a normal air/water heat pump and uses the finned heat exchanger on the source side and the plate exchanger B on the delivery side.

- Simultaneous Cooling and Domestic Hot Water Operation: The appliance behaves as a water/water heat pump and uses the plate exchanger of circuit A for domestic hot water and the plate exchanger of circuit B for cooling. Essentially providing free domestic hot water via the cooling process.

When Do You Choose Which System?

If you only need heating (hot water or space heating doesn’t matter) or only cooling, a 2-pipe system is sufficient. However, if you also need cooling at the same time, you choose a 4-pipe system or, as is sometimes done, 2 x a 2-pipe system.

Simultaneous heating and cooling occurs, for example, in office buildings that have a north and a south side. If the sun shines all day on the south side, there is a need for cooling, while heating may still be desired on the north side. A 4-pipe system is also desirable in the event that there is a very high need for hot tap water in addition to cooling.

4 Pipe system selection should be based upon the amount possible heat recovery available from the cooling process. Once the heat recovery base load is known, best practice would be to use 2 Pipe ASHPs and Chillers to the complete the system selection.

If we look at an example system sizing and selection, we can further explore the best way to select and design a simultaneous Heating and Cooling system…

Example

Building Location: London, Average Climate -3°C Outside Air Temperature (Heating), 30°C Outside Air Temperature (Cooling).

- Heating Load: 300kW, 45°C Flow

- Cooling Load: 350kW, 6°C Flow

- Proportion of peak heat recovery from the cooling process: 25% or 75kW

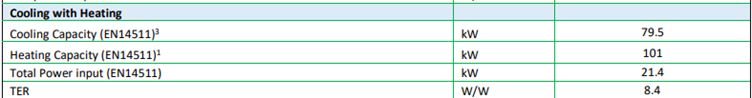

We now select a suitable 4 Pipe ASHP that can meet the peak demand of 75kW Heat Recovery from the Cooling process. Which in this case is x1no. LAHP-65HTR2904P Amicus Altus 4 Pipe Air Source Heat Pump. Selected due to its very high efficiency TER of 8.4 (For every kW used in electrical power this ASHP will deliver 8.4kW of Cooling and Heating on a ratio of 8.4:1).

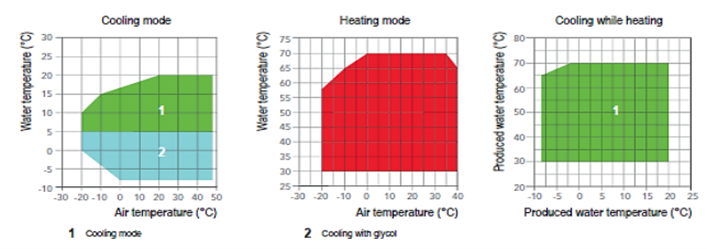

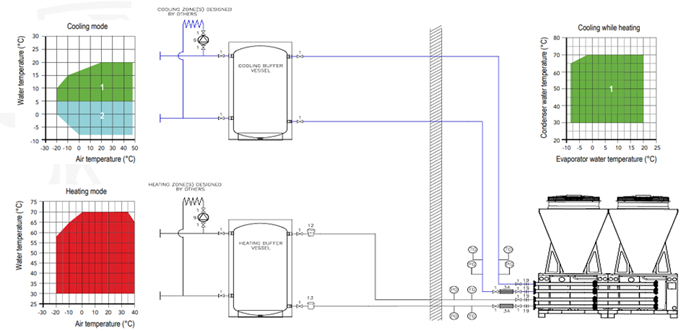

Fig 1. Amicus Altus 4 Pipe Performance Data

Fig 2. Amicus Altus 4 Pipe Operational Limits

The next step is to select suitable 2 pipe ASHPs and Chillers to match the rest of the heating and cooling load…

- Heating: 300kW minus the capacity of the 4 Pipe ASHP in heating only mode; 65kW, -3°C OAT = 235kW with a SCOP of 3.5

- Requires x1 LAHP260HTR290 (Consisting of x4 Amicus Altus R290 Heat ASHPs)

- Cooling: 350kW minus the capacity of 4 Pipe ASHP in Cooling only mode; 70kW, 30°C OAT = 280kW with a SEER of 4.58

- Requires x1 LAHP260HTR290RV (Consisting of x4 Amicus Altus R290 Chillers)

The only missing components are the buffers, sized to 20ltrs per kW / by the number of compressors (x2no per module) which equals 1000ltrs for the heating and 1000ltrs for the cooling.

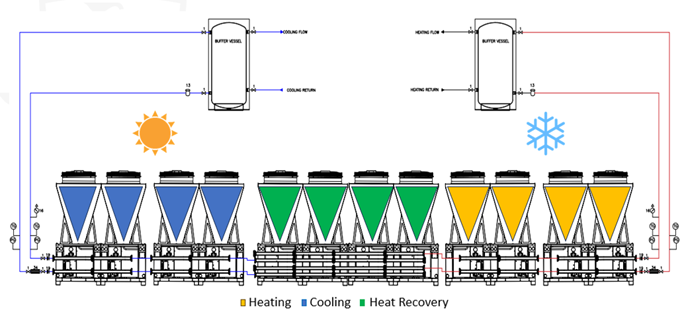

System Design DWG

Fig 3. Multiple R290 units

Fig 4. Single Unit

Recovery

If we look at the global climate goals, heat recovery or cold recovery is of course the most interesting option. Instead of COP (Coefficient of performance) we use the abbreviation TER (Total Efficiency Ratio). This is a combination of COP for heating and EER (Energy Efficiency Ratio) which is more common in cooling. In constructions where energy recovery is involved, the TER values can rise to 7 or 8. This means that the energy put into the device to function (electricity) yields 7 or 8 x its own efficiency.

Lochinvar 2-Pipe and 4-Pipe Solutions

Lochinvar’s latest commercial air-source heat pump, the Amicus Altus, is based on R290 refrigerant, which offers a low GWP of just 3. Our Altus units are fully cascadable with outputs of up to 880kW and can be configured for 2-pipe and 4-pipe configurations.

Lochinvar are a specialist provider of heating and cooling systems and unlike other manufacturers, all Altus installations benefit from specialist project support with project engineer site visits and commissioning as standard. Talk to our expert team today for more information about our sustainable heating and cooling systems.